Gain an impression

We have almost 20 years of experience in a wide range of more than 40 projects. The following selection in the field of product development shows you our diverse and comprehensive application possibilities in the areas: Automotive, Energy Systems, Facility Technology, Household Appliances, Medical Technology, ... Please understand that we cannot disclose all details for reasons of customer protection.

Power plant filter

Task

We were asked to find the cause of vibrations within a gas pressure control and measuring system. After investigating the flow behaviour, these could be attributed to the asymmetrical and swirling outflow from the filter. The filter is used to separate solids (e.g. rust particles) and liquids from the gas.

Solution

By adapting the internal components (while retaining the original filter cartridges), it was possible to achieve a uniform filter outflow. The separation efficiency was increased, the required installation space reduced and the pressure loss halved. The halved pressure loss leads to a (hydraulic) power saving of approx. 15,000 W (corresponds to 2.5 MWh per week when operating 24/7).

Film drying

Task

In a "wetgate" film scanner, the film leaves the apparatus too wet, it drips. The nozzles (called Air-Knifes) used for drying do not manage to blow the tetrachloroethylene (PER) off the film to a sufficient extent. The optimised nozzles should be plug'n'play interchangeable.

Solution

The redesigned nozzles convert the available compressed air into kinetic energy much more efficiently. So efficient that the inlet pressure can be reduced by approx. 20 %. Now the film is wound up without dripping. Shown are the velocity fields in the middle of the film.

Intake pipe

Task

We were asked to design an intake distribution pipe for the adaptation of a larger throttle. The aim is to de-throttle the intake for the purpose of increasing performance.

Solution

Our flow-optimised design can be used plug'n'play without restrictions as a functional prototype (or as small series production). Manufactured via 3D printing (MJFMulti Jet Fusion).

Radial fan

Task

As a component of a household appliance, a radial fan is to be optimised so that the overall appliance achieves a better EEIEnergy Efficiency Index. The spiral housing must not be changed in order to keep the injection moulding tool costs low. An acoustic improvement is also desirable.

Solution

Our design does increase the (static) efficiency of the fan by approx. 50 %. This corresponds to a (hydraulic) power saving of 11 W. Calculated per 100,000 units, this amounts to 1.1 MW, „just“ with a smarter fan design. The operating noise could be reduced by approx. 3 db. (all velocity scales are identical)

Ultrasonic water meter

Task

The flow behavior of a water meter shall be investigated, since it issues too high measuring uncertainties in some operating points. This is supposed to be usable for a very large dynamic rangeMaximum to minimum flow ratio (240 in this case). The currently used sensors (transducer) are to be retained.

Solution

Our designed variant fulfils all requirements. The flow in the measuring area is much more even which leads to lower measuring uncertainties over the hole operating range. In addition, the pressure loss is approx. 30 % lower.

Dust trap

Task

The currently used dust trap filters dust, largely consisting of iron oxide, by means of a glass fibre filter mat. It is to be investigated whether this mat can be substituted by a "smart" flow guidance.

Solution

Our final design meets all requirements and does not need an additional filter mat. The standard test regarding the filter rate has been passed. Compared to the reference, the pressure loss could be reduced by approx. 20 %.

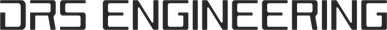

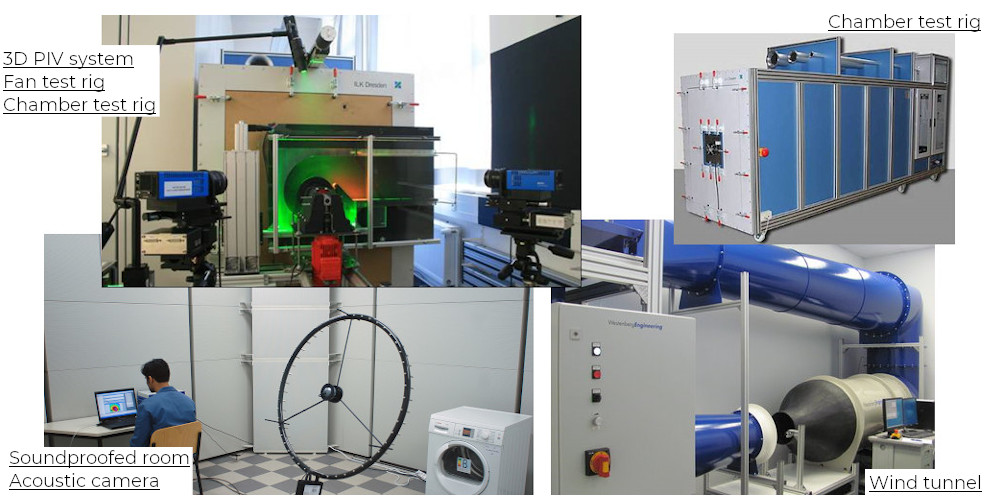

Fluid mechanics laboratory

Task

Selection of measurement technology, project planning and construction supervision. The available space must be used optimally. Research and teaching shall be possible in the same way.

Solution

The laboratory is now (among other things) equipped with: soundproofed room, acoustic camera (beamforming), chamber test rig, 3D PIVParticle Image Velocimetry system, small wind tunnel. The floor planning also allows the combination of different test benches, e.g. chamber test rig and soundproofed room.

Room ventilation

Task

Design of a retrofittable (with little effort) ventilation system for classrooms. The room air should be "exchanged" at least three times per hour without causing discomfort (due to draughts) to the people. The natural convection occurring in this room due to human waste heat should be effectively supported.

Solution

Our presented concept fulfils all requirements. The air exchange takes place four times per hour and can be supported by a HEPAHigh Efficiency-Particulate Airfilter filter. The maximum air velocity is (still) below 15 cm/s and is therefore uncritical according to the german workplace directive ASR A 3.6. The distribution of aerosols in the room is effectively reduced.

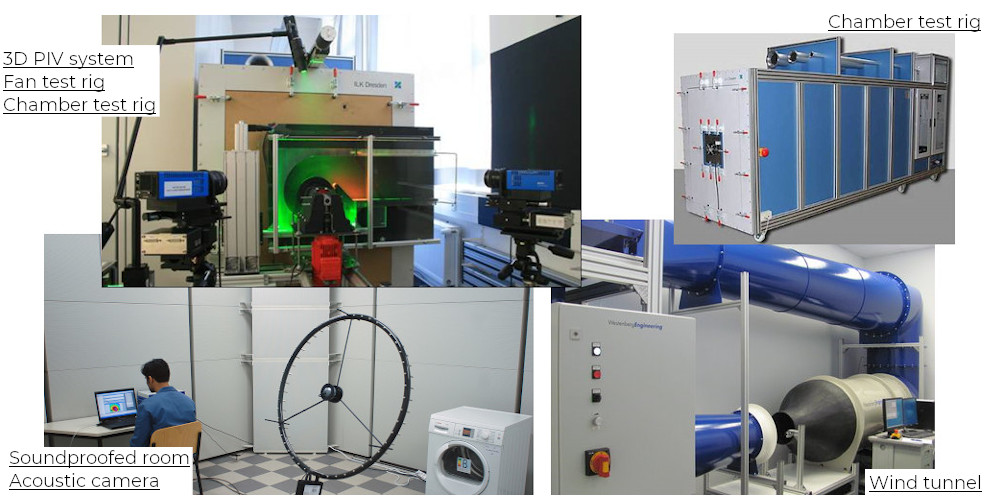

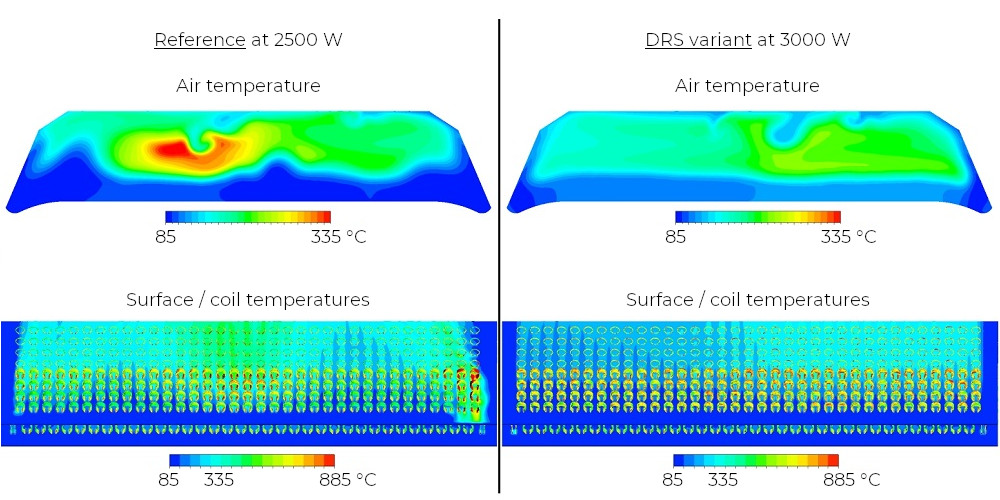

Heater

Task

The existing heating system shall be optimised with regard to its heat distribution. The aim is to increase the heat output without increasing the fire hazard due to hot spots. Trials with different heating coil arrangements did not bring the desired success.

Solution

Due to the optimised inflow conditions, the heat power can easily be increased by 20 %. The temperature distribution is now much more even. At the same time, the maximum temperature at the outlet can be reduced by 100 °C.

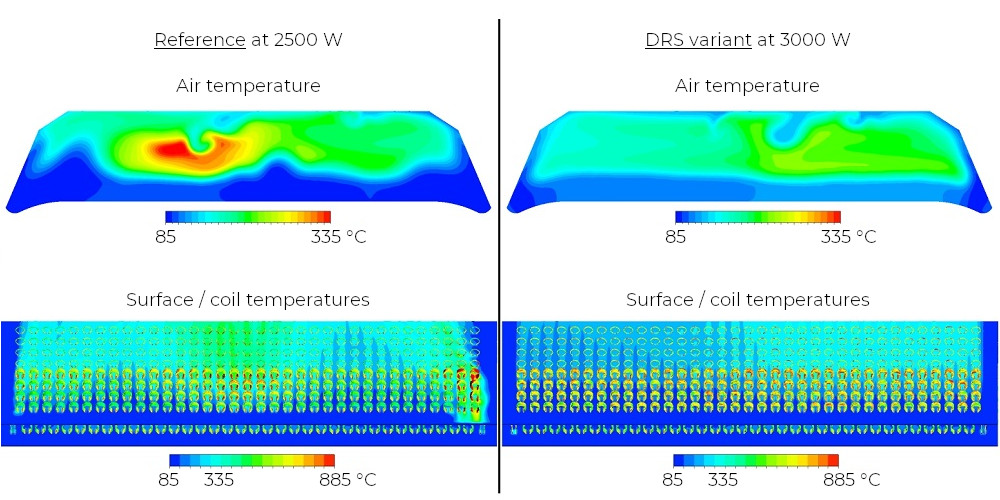

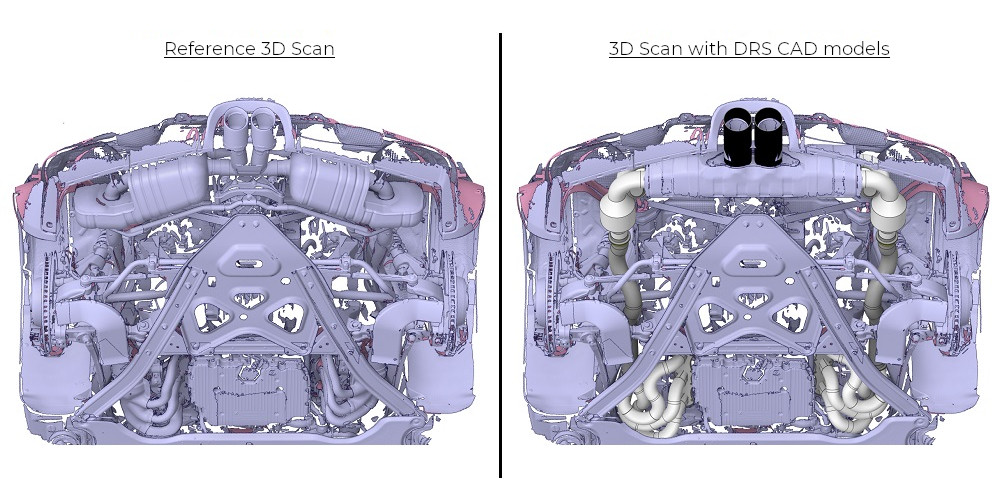

Exhaust system

Task

The exhaust system of a sports car is to be optimised for the purpose of increasing performance. Sufficient distance to heat-sensitive components (e.g. ignition coils) must be ensured. No parts may protrude from the underbody. In order to optimally use the available installation space while retaining the catalytic converters, we have digitally captured the underbody / engine with our 3D scanner.

Solution

Our design fulfils all requirements. The primary tubes are larger in diameter, equal long (their lengths differ only ± 2 mm or << 1 %) and designed symmetrically left / right. Due to identical (large) bending radii, the primary tubes can be produced efficiently using a CNC bending machine. The titanium muffler (from another model) features a X-pipe, which further improves the gas exchange.

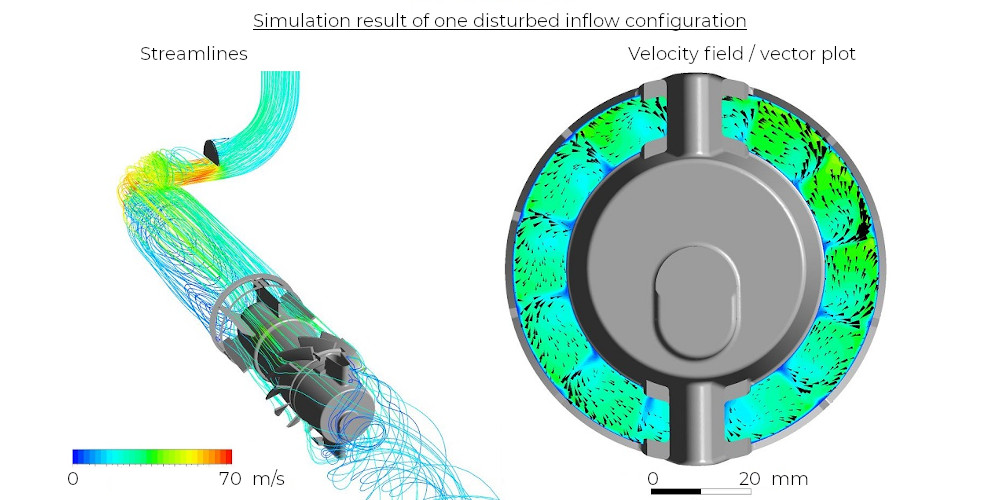

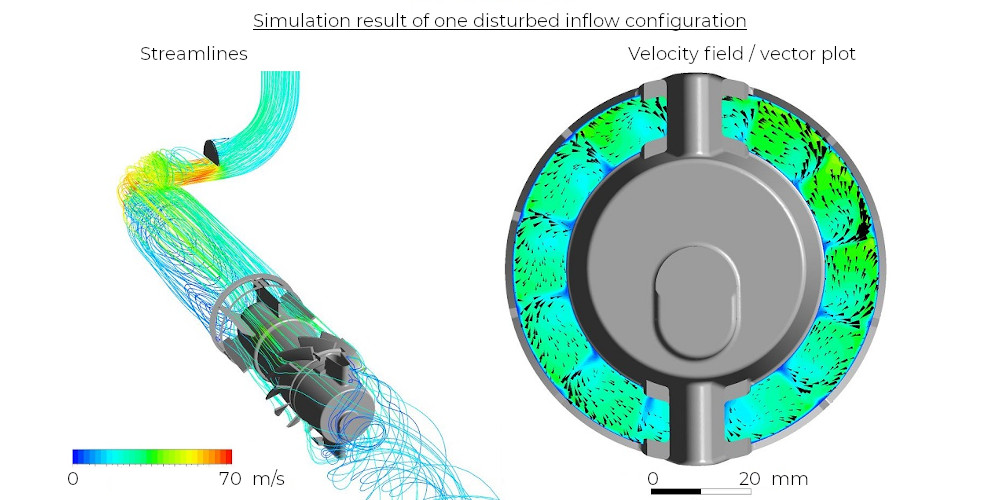

Axial wheel meter

Task

The existing axial wheel gas meter is to be investigated for its operating behaviour at different, disturbed inflows. Based on these findings, the rectifier element in front of the impeller shall be optimised.

Solution

Numerical simulations were used to identify the key areas. By making small changes to the rectifier, the operating behaviour is now constant over all (disturbed) inflow conditions.

Aerodynamics

Task

A sports car is to be equipped with "plug'n'play" add-on parts to improve aerodynamics. The available rear wing is being investigated in different heights, angles of attack (AOA) and with and without Gurney. The add-on parts are intended to reduce lift or convert it into downforce while increasing drag as little as possible.

Solution

In the variant shown, the lift of the reference model (approx. 600 N) is in combination with the canards transformed into double downforce. At the same time the drag coefficient increases relatively low by 0.024 points. (Calculations base on a modified DrivAer model, pictures show results at 250 km/h).

Intra okular lenses

Task

A test bench is to be developed for the in-vitro testing of the next generations of intraocular lenses. This will be used to stretch / compress / tilt the lenses and analyse the influence on the optical properties / refraction of light. The test bench shall be equipped with actuators and sensors to determine the force-displacement characteristics. The use of OCToptical coherence tomography must be made feasible. The investigation of real eyes should also be possible.

Solution

Our test bench fulfils all requirements and includes an additional preparation station. During the analysis and concept phase, several possible implementation approaches were identified. The most promising concept was produced in advance as a 1:1 model using 3D printing in order to be able to understand the handling and individual work steps. The final test bench was manufactured using high-precision CNC machines and uses eight force sensors and actuators.

Projects Overview by Industry

Vehicle and power unit electric drives

- Conception of multidisciplinary simulation workflow: CFD, FEM, EM, material design

- Script-based design rotor / stator (30 parameters)

- Parameter study permanently energized reluctance machine (EM)

- Stress analysis rotor / stator (FEM, CFD, CHT)

- Parameter study DC DC converter (EM)

- Optimization DC DC converter cooler (CFD, CHT; Pcool + 20 %)

- Material model validation through internal test series

- Virtual tensile / bending test (FEM)

Lightweight rims made of aluminium and magnesium alloy

- Conception incl. topology optimzation

- Realisation of rim designs (f/r) under lightweight aspects

- Validation of structural integrity and fitment (FEM, vehicle measurements)

- Accompaniment of acceptance tests to obtain regulatory assessment certificates

High Performance exhaust system

- Conception and design based on own 3D scans

- Validation of the design (CFD, literature data)

Canards und rear wing

- Conception and design based on own 3D scans (cA + 100 %)

- Validation of the design (CFD)

Intercooler (Charge-air cooler)

- Optimization / rearrangement of the radiator mesh (dp - 50 %)

- Validation of the design (CFD)

Lift kit, pneumatic front axle lift

- Conception and design as well as implementation of operation like OEM

Intake manifold for larger throttle / flow improvement

- Conception and design based on package room analysis

Chassis for track operation

- Adjusted tie rods / control arms as well as adjustment of camber, toe, wheel loads (road test)

Mini G4 gas meter (ultrasonic / calorimetric, e.g. according to ISO 17089)

- Conception ultra compact housing (1,5 l) incl. smart dust protection

- Conception for use of static and calorimetric sensors

- Ensuring function for accuracy class 1 (CFD, CHT, lab)

Modular G10-G40 gas meter (ultrasonic, e.g. according to ISO 17089)

- Conception and design of modular housing for different meter classes and country variants

- Conception and design of passive components for measuring range extension

- Ensuring function for accuracy class 1 (CFD, CHT, lab)

Dust protection for G4 gas meter

- Conception and design of smart gas routing without filter insert

- Validation of the design (CFD, lab)

Dust / liquid separators (GDRM stations, e.g. according to DVGW G 491)

- Optimization / rearrangement of internal structures (dp - 50 %, tweld - 10 %)

- Validation of the design (CFD)

Compact water meter (ultrasonic, e.g. according to OIML R49)

- Conception and design for vortex-free, homogeneous water flow

- Validation of the design (CFD)

Water meter (DN150, turbine wheel)

- Simulation of disturbed inflow and its effect (CFD)

Heat pump heating system (e.g. according to DIN TS 12831, ISO 5149, VDI 6030)

- Implementation of Kanban-based, four-stage Technical Survey / Design Process (TS / TD)

- Specification of quality criteria and checklists for TS / TD

- Specification of standardized customer informations after TS / TD (90 % less queries)

- Implementation of interdisciplinary, needs-based personnel deployment

- Creation of standardized tools for radiator power calculation and selection (xls)

- Conception for reduction supply chain complexity radiators and valves as well as standard installation

- Specification of installation requirements for special installations (additional EUR 600k turnover)

Test rig design (e.g. according to DIN EN 1319, DIN EN 60335, DIN EN IEC 60379, DIN EN IEC 63159)

- Conception of test benches for instantaneous water heaters, water storage tanks, pressure sensors

- Creation of analytical tools for functional / operational predictions (xls)

- Creation of the hydraulic plans (EPlan)

- Responsible for component selection

- Cost reduction through alternative choice of equipment (approx. EUR 70k for two test benches)

- Advice on solving errors in the test center (comparative and golden sample tests)

Room ventilation (retrofittable for classrooms / seminar rooms, e.g. according to ASR A3.6)

- Overall conception incl. fan, ventilation ducts, HEPA filter

- Validation of the design (CFD)

Laundry dryer (e.g. according to EN 60704, DIN EN 61121)

- Design / optimization of fans (CFD, lab; ηstat + 100 %, Lp - 2 dB)

- Optimization of air flow for half load (CFD, lab; Etot - 15 %, tdry - 15 %)

- Optimization of pump regarding lint (CFD, lab)

- Parameter study wire coil heating (CFD, CHT, lab; Pheat + 20 %, Tmax - 100 K)

- Parameter study heat exchanger (CFD, CHT)

- Parameter study thermal insulation (lab)

- Optimization of drying process (drying speed / energy consumption)

- Automatic tool for test evaluations (xls VBA; time requirement - 90 %, memory requirement - 99 %)

- Development of self-regulating actuator for cooling air adjustment

- Cost reduction through common parts strategy

- Coordination / support / implementation prototype assembly

Cooker hoods (e.g. according to IEC 60335, DIN EN IEC 61591)

- Conception and design for small installation spaces and disturbed inflow / outflow

- Optimization fan and airflow guidings (ηstat + 50 %, Lp - 3 dB)

- Validation of the design (CFD, lab)

Room humidifier (e.g. according to IEC 60335)

- Optimization fan and airflow guidings (ηstat + 20 %, Lp - 2 dB)

- Validation of the design (CFD, lab)

Test rigs (e.g. according to VDI 2044, ISO 5801, DIN 24163, DIN 45635)

- Selection of appropriate sensors / measurement equipment with regard to flow measurement

- Automatic script for evaluation of operating and environmental data incl. noises (xls, LabView)

- Training on operation and maintenance (e.g. pressure test regarding leaks)

Test rig (e.g. according to DIN EN ISO 13485, DIN EN ISO 11979)

- Concept for mechanical / optical measurements of accommodating intraocular lenses

- Modular test rig design incl. sensors / actuators

- Software adaptations (GUI)

- Realisation of acceptance tests

Positioning device for cutting / marking of intraocular lenses (e.g. in accordance with DIN EN ISO 13485, DIN EN ISO 11979)

- Conception of modular positioning device

- Design work

- Commissioning of IR laser system (100 μJ) incl. implementation of acceptance tests

- Assessment of surface qualities (microscope, profile projector, white light interferometer)

Ventilator (e.g. according to DIN EN ISO 3744, DIN EN ISO 23372, DIN 45635, DIN EN 60601)

- Conception of real-time capable 1D function simulation (xls, C)

- Digital twin concept

- Optimization air / O2 mixing chamber (dp - 30 %, improvement of O2 measurement)

- Optimization of volume flow measurement by means of suitable sensors

- Script for the evaluation of operating and environmental variables incl. noises (xls)

- Conception and design exhaust system with floating body indicators

- Simulation ball drop test (FEM)

Dental power tool (e.g. according to DIN EN ISO 7786)

- Development of test procedures for human-machine interaction (traffic light system in xls)

- Creation, execution, evaluation of test sequences

- Optimization of machining processes and extension of functional range / logging

- Release of firmware versions for further use in the CAM / manufacturing departments

- Implementation of "part loose" logic on the basis of existing measured values

- Support for series start-up in production

Steam sterilizer

- Determination of pressure loss, heat / velocity distribution (CFD, CHT)

- Optimization of rotary actuator for uniform mass flow distribution and small angles of rotation

- Reduction of cavitation risk by means of detail optimization

Film scanner

- Wet scan through virtually bubble-free rinsing

- Validation of the design (CFD, VOF, lab)

- Parts design

Film drying air nozzles

- Smart design enables higher drying capacity at lower inlet pressure

- Validation of the design (CFD, lab)

- Parts design

Electron microscope

- Vibration analysis of natural frequencies and harmonics (FEM)

- Conception and design of heat pipe support

Advice in general

- Solution strategy (cause, effect)

- Efficient execution of simulations / measurement campaigns

- Prototyping / Reverse Engineering

- Plausibility check / evaluation of numerical and experimental data

- Cost awareness / sustainability

- Project leading / management

engineering office, CFD, computaional fluid dynamics, fluid mechanics, FEM, structural mechanics, simulation, topology optimisation, bionik, evolution strategy, CIP, Six Sigma, Lean Management, quality, innovation, efficiency, aerodynamic, air flow, fan, blower, pump