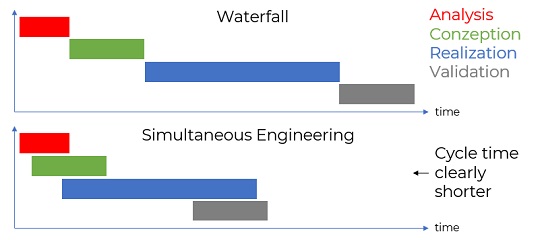

Our solution finding process in general runs through four phases: analysis of the task, conception of possible solutions, realization of suitable solutions and validation of the solution. We take a pragmatic approach and parallelize our activities wherever possible. For example, we already submit possible concept proposals to you during the basic, scrutinizing needs analysis. We start implementing potentially target-oriented solutions during the concept phase. We enter the procurement process for necessary parts that have long delivery times as soon as the concept has been approved, etc. This approach is also known as Simultaneous Engineering. In contrast, the „old school” often follows the so-called waterfall model. As the name suggests, the approach is strictly sequential and it is always waited until one phase is completed before the next one is started. Thus, Simultaneous Engineering always leads to much faster project completion. The entire process becomes agile when progress and goals are reflected in regular rounds and adapted to changing conditions. The resources freed up can be used for new approaches.

We handle one, several or all necessary activities within your project for you. From single working packages within our engineering services over project-lead up to project management. We support you in planning and controlling your processes in order to lead them to their goal on schedule with minimized effort / resources. This way, your goals are achieved by „plan & do” instead of messing around with „try & error” or „copy & fail”. Our almost 20 years of cross-industry project experience enables us to be your interdisciplinary and reliable partner.

We specialize in combining numerical simulations with experimental validation to analyze and optimize complex products. Our expertise ensures precise, data-driven solutions for improving performance, efficiency, and durability across various engineering applications. This is not limited to fluid mechanics, but also includes peripheral disciplines such as structural mechanicse.g. FEM topology optimization (see adjacent animation), thermodynamics and electromagnetics. Calculations or simulations enable us to develop or optimize efficient and sustainable products. In addition, simulations significantly reduce development time and the number of prototypes. Our services are complemented by experimental work for validation purposes, prototype procurement / testing and reverse engineering.

The creative solution finding is based on the ingeniousness and competence of the person sitting in front of the computer. This is where our second main area comes into play. We provide expert consulting for product development, specializing in refining fluid and mechanical designs, optimizing performance as well as improving manufacturability. Our expertise in lightweight design, fluid dynamics, and heat transfer leads always to reliable, tailor based solution. We assist you on the development / optimization of innovative products, from the concept phase to pilot production and use digital twin technology whereever applicable.

Beyond technical solutions, we provide project and interim management support, ensuring smooth execution and integration of engineering processes. Our structured approach, roots in methodologies like SCRUM, Six Sigma, and Lean Management. We assist or take over leadership in the main responsibilities like forming the project team, delegating tasks and monitoring their completion. We ensure the flow of knowledge between all participants / stakeholders and among other things elaborate content, sequences, schedules. If needed complemented by process development, e.g. by means of multistage Kanban.

For more information about our skills and abilities, please have a look on our range of services. You can also contact us directly and take advantage of your free initial consultation! We would be happy to explain the potentials to you based on your specific task / question.

Engineering office, Ansys CFX, Spaceclaim, CFD simulation, flow simulation, fluid mechanics, FEM simulation, topology optimisation, bionics, evolution strategy, CIP, Six Sigma, lean management, quality, innovation, efficiency, fan, pump